Wholesale Dealers Of Water Treatment Polyacrylamide - Polyacrylamide 90% For Paper Making Industry Application – Crownchem

Wholesale Dealers Of Water Treatment Polyacrylamide - Polyacrylamide 90% For Paper Making Industry Application – Crownchem Detail:

Application

PAM FOR PAPER MAKING INDUSTRY APPLICATION

1. Dispersing Agent for Paper Making

In paper making process, PAM is used as dispersing agent to prevent fiber agglomeration and improve paper evenness. Our product can be dissolved within 60 minutes. Low addition amount can promote the good dispersion of paper fiber and excellent paper forming effect, improving the evenness of pulp and the softness of paper, and increasing the strength of paper. It is suitable for toilet paper, napkin and other daily used paper.

| Model Number | Electric Density | Molecular Weight |

| Z7186 | Middle | High |

| Z7103 | Low | Middle |

2. Retention and Filter Agent for Paper Making

It can improve the retention rate of fiber, filler and other chemicals, bringing clean and stable wet chemical environment, saving the consumption of pulp and chemicals, reducing production costs, and improving paper quality and paper machine production efficiency. Good retention and filter agent is the prerequisite and necessary factor to ensure the smooth operation of the paper machine and good paper quality. High molecular weight polyacrylamide is more widely suitable for different PH value. (PH range 4-10).

| Model Number | Electric Density | Molecular Weight |

| Z9106 | Middle | Middle |

| Z9104 | Low | Middle |

3. Staple Fiber Recovery Dehydrator

Papermaking wastewater contains short and fine fibers. After flocculation and recovery, it is recycled by rolling dehydration and drying. The water content can be effectively reduced by using our product.

| Model Number | Electric Density | Molecular Weight |

| 9103 | Low | Low |

| 9102 | Low | Low |

3. Profile Control and Water Plugging Agent

According to different geological conditions and pore size, the molecular weight can be selected among 500,000 and 20 million, which can realize three different ways of profile control and water plugging function: delaying cross-linking, pre-crosslinking and secondary cross-linking.

| Model Number | Electric density | Molecular weight |

| 5011 | Very low | Extreme low |

| 7052 | Middle | Medium |

| 7226 | Middle | High |

Package:

·25kg PE bag

·25KG 3-in-1 composite bag with PE liner

·1000kg Jumbo Bag

Company Introduction

Exhibition

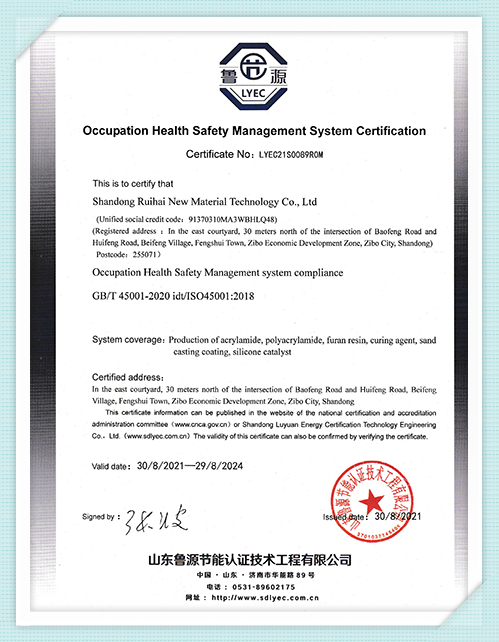

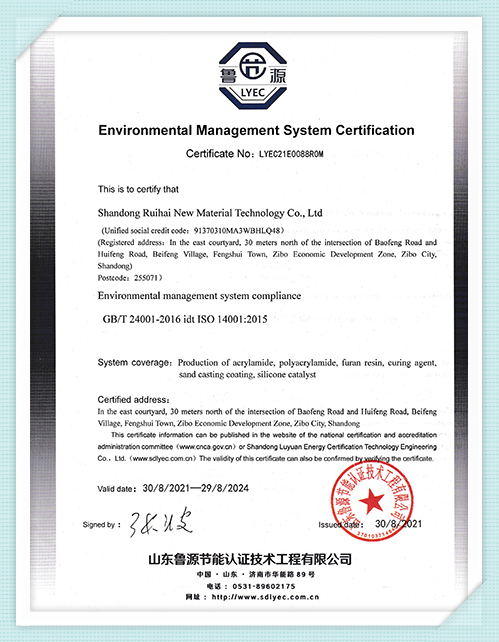

Certificate

FAQ

1. What are your prices?

Our prices are subject to change depending on supply and other market factors. We will send you an updated price list after your company contact us for further information.

2.Do you have a minimum order quantity?

Yes, we require all international orders to have an ongoing minimum order quantity. If you are looking to resell but in much smaller quantities, we recommend you check out our website.

3.Can you supply the relevant documentation?

Yes, we can provide most documentation including Certificates of Analysis / Conformance; Insurance; Origin, and other export documents where required.

4.What is the average lead time?

For samples, the lead time is about 7 days. For mass production, the lead time is 20-30 days after receiving the deposit payment. The lead times become effective when (1) we have received your deposit, and (2) we have your final approval for your products. If our lead times do not work with your deadline, please go over your requirements with your sale. In all cases we will try to accommodate your needs. In most cases we are able to do so.

5.What kinds of payment methods do you accept?

You can make the payment to our bank account, Western Union or PayPal:

30% deposit in advance, 70% balance against the copy of B/L.

Product detail pictures:

Related Product Guide:

We rely upon strategic thinking, constant modernisation in all segments, technological advances and of course upon our employees that directly participate inside our success for Wholesale Dealers Of Water Treatment Polyacrylamide - Polyacrylamide 90% For Paper Making Industry Application – Crownchem , The product will supply to all over the world, such as: Rwanda, Thailand, Morocco, Should any of these items be of interest to you, please let us know. We'll be satisfied to give you a quotation upon receipt of one's detailed specifications. We have our personal experienced R&D enginners to meet any of one's requriements, We appear forward to receiving your enquires soon'and hope to have the opportunity to work together with you in the future. Welcome to check out our company.

This supplier's raw material quality is stable and reliable, has always been in accordance with the requirements of our company to provide the goods that quality meet our requirements.