-

Application of furfuryl alcohol

Furfuryl alcohol, also known as furfuryl alcohol or furfural acid, is a kind of natural organic acid, widely exists in plants, especially in the bran layer of cereal crops. Furfuryl alcohol has a variety of biological activities and application value in medicine, food, chemical, environmental pro...Read more -

Chemical properties and uses of acrylamide

Acrylamide, is an organic compound, the chemical formula is C3H5NO, the appearance of white crystalline powder, soluble in water, ethanol, ether, acetone, insoluble in benzene, hexane. Acrylamide is one of the most important and simple acrylamide systems, and it is widely used. To be specific: 1...Read more -

Applications, properties, solubility and emergency methods of furfuryl alcohol

Furfural is the raw material of furfuryl alcohol, which is obtained by cracking and dehydrating polypentose contained in agricultural and sideline products. Furfural is hydrogenated to furfural alcohol under the condition of catalyst, and is the main raw material for furfuran resin production. Fu...Read more -

Itaconic Acid 99.6% MIN

Properties: Itaconic Acid (also called Methylene Succinic Acid) is a white crystalline carboxylic acid obtained by the fermentation of carbohydrates. It is soluble in water, ethanol and acetone. Unsaturated solid bond makes a conjugated system with carbonly group. It is used in the field of; C...Read more -

On furfuryl alcohol leakage emergency treatment

Evacuate the personnel from the contaminated area to the safety zone, prohibit irrelevant personnel from entering the contaminated area, and cut off the fire source. Emergency responders are advised to wear self-contained breathing apparatus and chemical protective clothing. Do not contact the le...Read more -

Furfuryl alcohol production technology

Our company cooperates with East China University of Science and Technology, and firstly adopts continuous reaction in kettle and Continuous distillation process for the production of Furfuryl alcohol. Entirely realized the reaction at low temperature and automatic remote operation, making the qu...Read more -

Furfuryl alcohol producer

Furfury Alcohol , Also Known As Furfuryl Alcohol, Is An Important Organic Chemical Raw Material. Its Industrial Production Was First Realized By Quaker Oats Company In 1948. Furfuryl Alcohol Is An Important Derivative Of Furfural, Which Is Prepared By Catalytic Hydrogenation Of Furfural In Gas O...Read more -

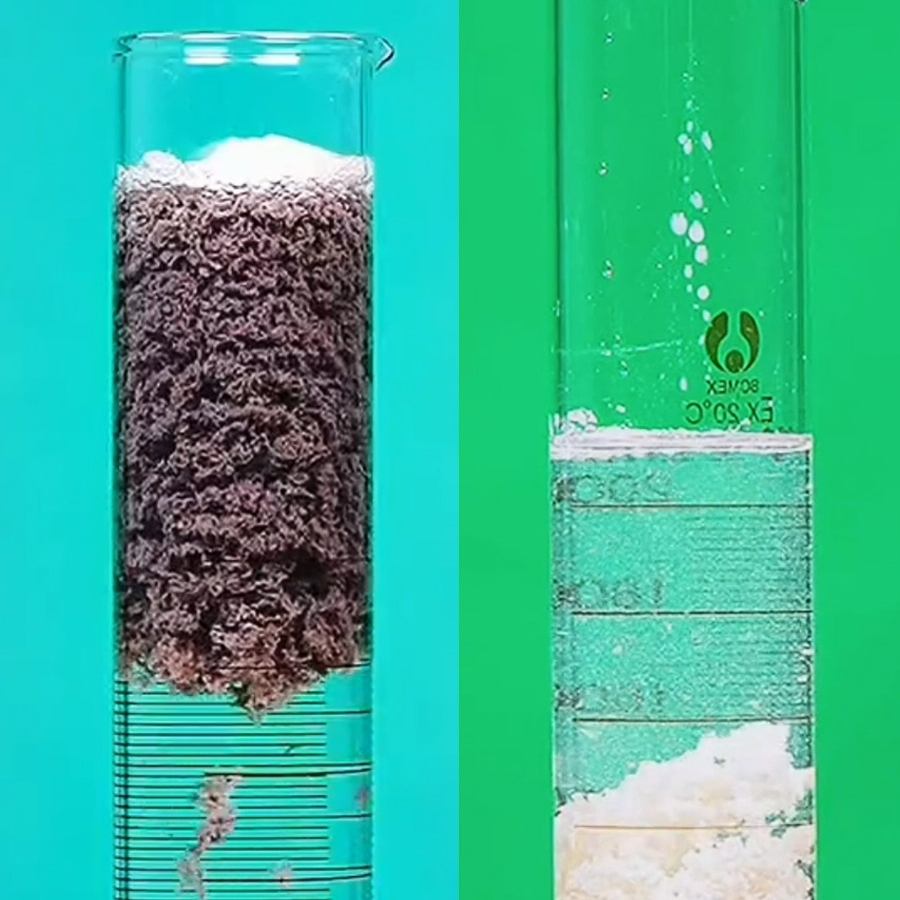

Modified aluminum hydroxide—Flame-retardant material

Aluminum hydroxide powder with flame retardant, smoke elimination, filling and other multiple functions, can produce synergistic flame retardant effect with phosphorus and other substances, is a wide range of chemical products, has become electronic, chemical, cable, plastics, rubber and other in...Read more -

Application of furfuryl alcohol

Furfuryl alcohol is an important organic chemical raw material. Mainly used in the production of various properties of furan resin, furfuryl alcohol urea formaldehyde resin and phenolic resin. Hydrogenation can produce tetrahydrofurfuryl alcohol, which is a good solvent for varnish, pigment and r...Read more -

The main sources and characteristics of industrial wastewater

Water/wastewater treatment plant A by-product of sewage treatment plants is the production of waste containing many potential pollutants. Even chlorinated recycled water can contain disinfectant byproducts such as trihalomethane and haloacetic acid. Solid residues from sewage treatment plants, c...Read more -

Polyacrylamide 90%

Polyacrylamide 90% Polyacrylamide is a linear water-soluble polymer, based on its structure, which can be divided into non-ionic, anionic and cationic polyacrylamide. Known as “Auxiliary Agent for all industries”, it is widely used in various fields such as water treatment, oil field, minin...Read more -

Acrylonitrile: In which industries is it used most? What is the future of acrylonitrile?

Acrylonitrile is produced by oxidation reaction and refining process using propylene and ammonia water as raw materials.Is a kind of organic compounds, chemical formula C3H3N, is a colorless pungent liquid, flammable, the vapor and air can form explosive mixture, in the case of open fire, high he...Read more